Cement- the Bond !

Disclaimer: Information provided is for informational purposes only and not a substitute for professional advice, and that any reliance on this information is at your own risk, emphasizing that the provider is not liable for any losses or damages incurred.

Which type of cement is best for house construction in India?

For most homes, PPC (Portland Pozzolana Cement) is preferred due to its long-term durability, especially in damp climates, while OPC (Ordinary Portland Cement) is used when early strength is needed.How do I check the quality or freshness of cement before buying?

Check the manufacturing date on the bag—cement should be used within 3 months of manufacture. Good cement feels smooth when rubbed, is uniform in color, and sinks in water without floating.What are the differences between OPC and PPC cement; which should I choose?

OPC gives quick strength and is good for urgent construction needs, whereas PPC sets slower but is more durable and resistant to harsh weather and chemicals.Can I use one type of cement for the whole house?

Usually, PPC can be used for most parts of a house, but some areas like foundations or heavy load-bearing sections may benefit from OPC for faster strength gain.How does the choice of cement affect durability, weather, and moisture?

PPC resists moisture and weathering better, making it ideal for bathrooms, roofs, and coastal regions, while OPC is suitable for quick construction in dry areas.Is it safe to use cement from local brands, or only major brands?

Always buy from ISI-marked, BIS-certified brands—well-known or reputed local brands are fine if they have these certifications and proper packaging.What is the cost difference between major and local cement brands; does it reflect quality?

Major brands may cost more but often guarantee consistent quality; some local brands are good but always check for certifications before purchasing.How long can cement be stored, and how should it be stored?

Cement should ideally be used within 3 months of manufacturing and kept in a dry, raised area with plastic sheets to avoid contact with moisture.What is the correct water-cement ratio for home construction?

The general ratio is about 0.4–0.6 parts water by weight to 1 part cement, but follow your engineer’s or manufacturer’s recommendation for best results.What approvals, IS codes, or accreditations should I check when buying cement?

Look for the ISI mark and check that the cement conforms to relevant IS codes (like IS 269 for OPC-33, IS 1489 for PPC) to ensure safety and compliance.What mistakes should be avoided when using cement during construction?

Don’t use old or lumpy cement, avoid mixing with too much water, always cure freshly laid cement, and keep it covered from moisture until used.

Hey, found some interesting stuff for you – wanna check it out?

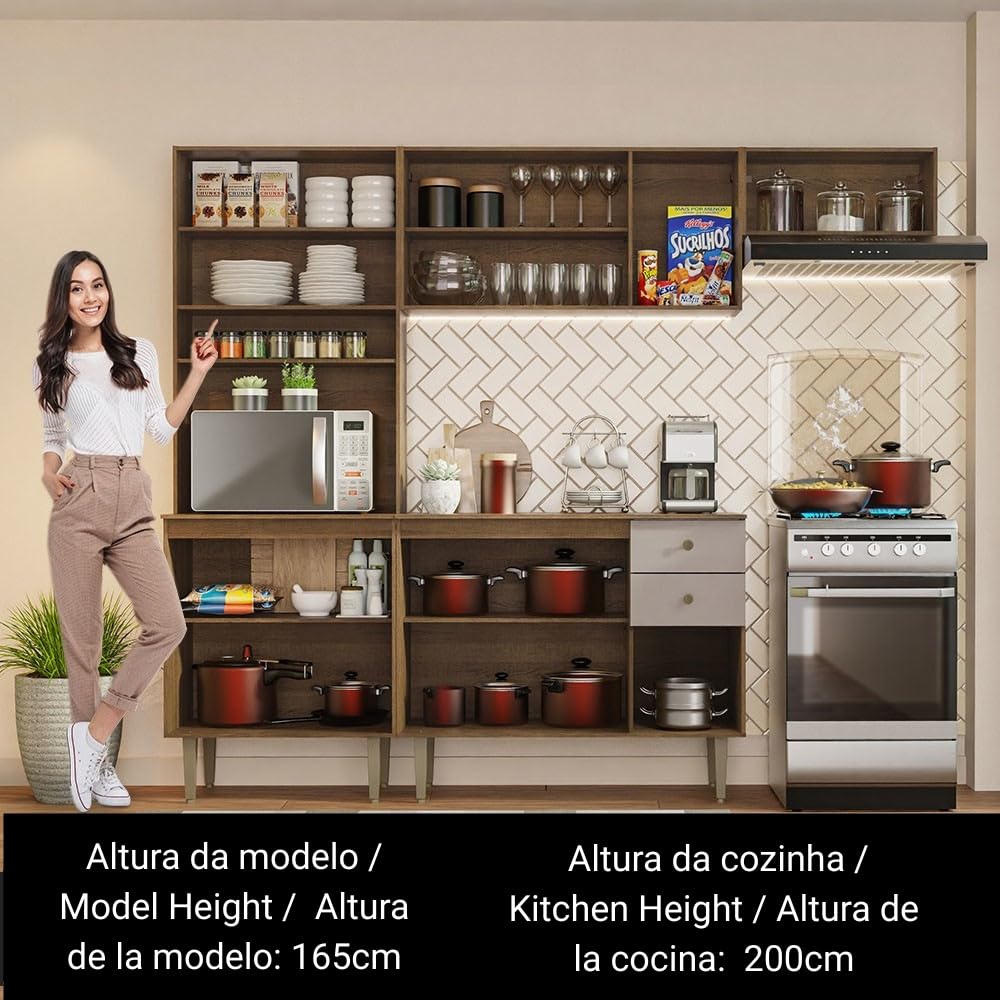

40% Off !

Multiple Compartments

Product Dimensions: 235 cm W x 200 cm H x 44 cm D

FAQ

Cement Types- OPC vs PPC - Where to use?

OPC– Building Structure like Columns, Beams, Roof Slab. In coastal region, use PPC.

PPC– Can generally be used everywhere.

How many bags required? (Structure with columns)

2200 sft, 4 BHK Ground + 1 Floor – 950 Bags

How much do Architects charge?

Again, very general answer – 5% of construction cost

Should I engage a Structural Engineer?

Always, YES. Not only to ensure safety, also they will save you money. They may charge Rs.7 – 12 per Sft. Normally this fee is included in Architect’s fee.

Should I give a Labor Contract or Full Material contract?

Simple answer- If you have 3-4 hours to spend on site “every day” go for labor contract otherwise Full contract. If going for Labor contract, hire a professional for advice.

How to ensure that Cement is mixed in right proportion?

Procure a measurement box made of MS (mild steel). So now if ratio says 1:4, measure [one box cement] and [4 boxes sand/m-sand]. Similarly if concrete says 1:2:4, measure [cement 1 box], [Sand 2 boxes] and [aggregate- 4 boxes].

Customers Speak

YOUR REQUIREMENT

BEST CHOICE

WHY?

Need slab removed soon, fast build

OPC 53 (UltraTech/Birla)

Early high strength, quick set

Building in humid/coastal area

PPC/PSC (Ambuja/Dalmia)

Resists moisture, salt

Want lowest price, longer working time

PPC/OPC (Dalmia/ACC)

Cheaper & workable

Buying big brand, city site

UltraTech/Birla/Ambuja

Easy to source, guaranteed QC

Prefer longer setting in summer

Birla Super 53-Grade

More workable time

Useful Stuff For your Home

Some NICE things that every home needs. Few pointers to help you decide

GRANOTONE Floor Paint

Floor paints protect surfaces from moisture, dust, stains, and wear, extending floor life.

They instantly enhance appearance with smooth, colorful finishes and design options.

Easy to clean and maintain, making them ideal for homes, garages, and commercial spaces.

Options with anti-slip and chemical resistance improve safety and durability.

A cost-effective makeover that’s DIY-friendly and great for both aesthetics and function.

Pureit Eco Water Saver RO+UV+MF+Mineral

RO removes harmful dissolved salts, heavy metals, and impurities

UV technology kills bacteria, viruses and other microorganisms without chemicals.

MF (Microfiltration) adds another layer of protection by filtering out fine particles.

Mineral Cartridge restores essential minerals like calcium and magnesium for better taste and health.

Together, they ensure safe, tasty, and healthy drinking water for your entire family.

|

Cement Type |

Pros |

Cons |

|

OPC |

– High early compressive strength, suitable for rapid construction123. |

– High heat of hydration can lead to cracks in large pours25. |

|

PPC |

– Improved long-term strength and durability, especially in aggressive environments6789. |

– Gains strength more slowly; lower early strength8411. |

|

PSC |

– Excellent durability with strong resistance to chemical attacks (sulphates, chlorides)—ideal for marine, industrial, or mass concrete applications121314159. |

– Slower early strength gain compared to OPC12152. |

- OPC – ideal for projects needing quick strength and early load-bearing, but has a high environmental cost and is less durable in harsh conditions.

- PPC – offers superior long-term durability, eco-friendliness, and less cracking but is slower in strength gain and less suited for urgent timelines.

- PSC – is best for durability and chemical resistance, especially in large or aggressive environments, though its slower early strength may delay construction.

Disclosure: As an Amazon Associate, I earn from qualifying purchases. This does not affect the price you pay.